PDR for steel panels offers an eco-friendly, non-destructive approach to auto body repair, minimizing waste, conserving resources, and enhancing sustainability with efficient frame straightening and swift repair times. Proven successful in automotive restoration, PDR preserves historical integrity while reducing environmental impact, workplace pollution, and hazardous chemical use, setting new eco-friendly standards globally.

Discover the innovative and eco-friendly approach to panel restoration through PDR (Paint Damage Repair) for steel panels. This gentle, non-invasive technique offers a sustainable solution for revamping industrial aesthetics. By avoiding harsh chemicals and heavy sanding, PDR minimizes waste and environmental impact. Learn how this method benefits both the planet and your bottom line with enhanced durability and reduced costs. Explore real-world case studies showcasing successful transformations using PDR’s effective, green restoration techniques.

- Understanding PDR: A Gentle Restoration Technique

- Benefits for Steel Panels: Eco-Friendliness Enhanced

- Case Studies: Transforming Steels with PDR Methods

Understanding PDR: A Gentle Restoration Technique

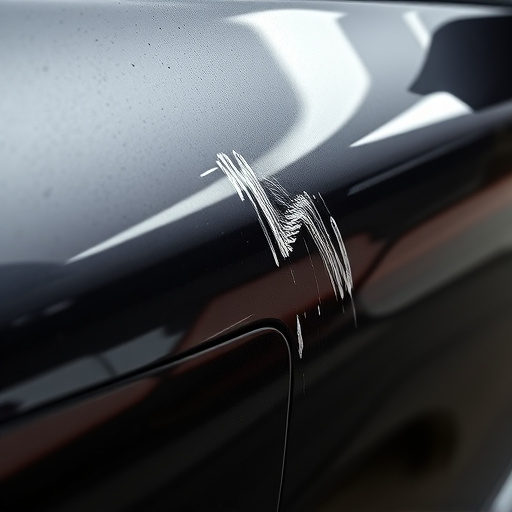

PDR, or Paintless Dent Repair, is a specialized technique that offers an eco-friendly solution for restoring damaged steel panels. Unlike traditional repair methods that often involve harsh chemicals and extensive sanding, PDR is a gentle process designed to remove dents and dings without affecting the original finish. This method has gained popularity in various industries, including automotive restoration, due to its minimal waste production. By skillfully using specialized tools to press and mold the metal back to its original shape, PDR technicians can effectively fix dents on steel panels, from car bodies to industrial machinery.

This innovative technique is particularly advantageous for steel panels as it preserves the panel’s structural integrity and cosmetic appeal. Unlike auto glass repair or even automotive repair services that may leave visible scars, PDR leaves no traces of its presence, ensuring the panel looks as good as new. This not only reduces the environmental impact but also extends the life of the panel by minimizing the need for frequent replacements, contributing to a more sustainable approach in the automotive and manufacturing sectors.

Benefits for Steel Panels: Eco-Friendliness Enhanced

The use of PDR for steel panels offers a multitude of benefits, with eco-friendliness being a standout advantage. This non-destructive repair technique minimizes waste generation, as it allows for the restoration and reuse of damaged steel surfaces. By avoiding traditional cutting or replacement methods, PDR conserves resources and reduces the environmental impact commonly associated with auto body repairs, making it an eco-conscious choice.

Furthermore, PDR’s efficiency in frame straightening contributes to a greener outcome. Repairs can be completed swiftly, reducing the energy consumption typically required for intensive metal fabrication processes. This method also minimizes the need for hazardous chemicals and materials often used in auto glass replacement or other repair techniques, making it a safer and more sustainable option for both workers and the environment.

Case Studies: Transforming Steels with PDR Methods

In the realm of eco-friendly transformations, Professional Detailing Restoration (PDR) for steel panels stands out as a game changer. This non-invasive technique has been meticulously applied to various case studies involving automotive and industrial steel structures, showcasing its versatility and sustainability. For instance, an auto body shop specializing in car restoration utilized PDR methods to revive damaged steel panels on vintage vehicles without resorting to traditional painting or auto body repairs. This approach not only preserved the historical integrity of the cars but also significantly reduced the environmental footprint associated with typical auto painting processes.

Another remarkable study involved a bustling, eco-conscious auto shop that employed PDR for steel panel repair in their daily operations. By minimizing the need for harmful chemicals and discarding old panels, this innovative method has contributed to a cleaner workplace and reduced waste output. The outcome? A restored, sleek finish comparable to that achieved through traditional auto painting, but with an emphasis on sustainability. These case studies exemplify how PDR for steel panels is revolutionizing not only the car restoration industry but also setting new standards for eco-friendly practices in auto body shops worldwide.

PDR (Paintless Dent Repair) offers a sustainable solution for restoring and recycling steel panels, making it an eco-friendly choice. By minimizing waste and the need for harsh chemicals or new paint, this gentle restoration technique not only preserves the life of steel surfaces but also contributes to a greener environment. As demonstrated in the case studies, PDR methods can transform damaged steel panels, extending their lifespan and reducing the demand for resource-intensive manufacturing processes. Adopting PDR for steel panels is a step towards a more sustainable future, where beauty and functionality can coexist with ecological responsibility.